Apr. 09, 2022

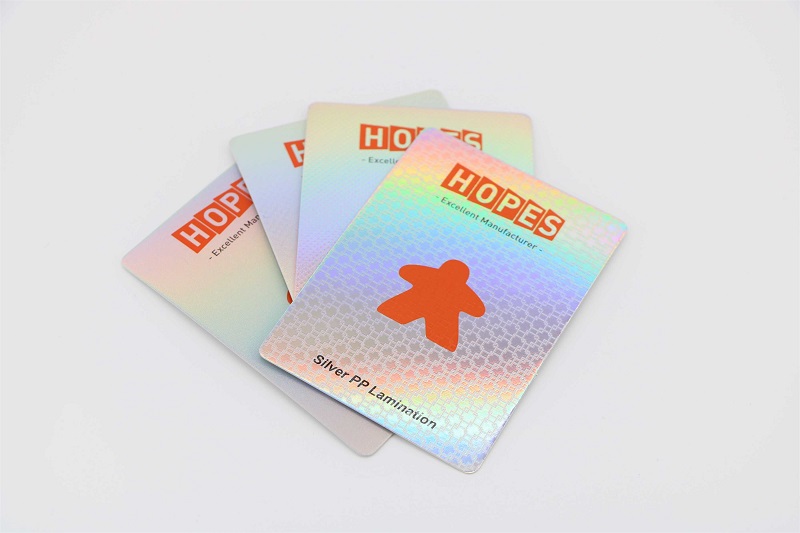

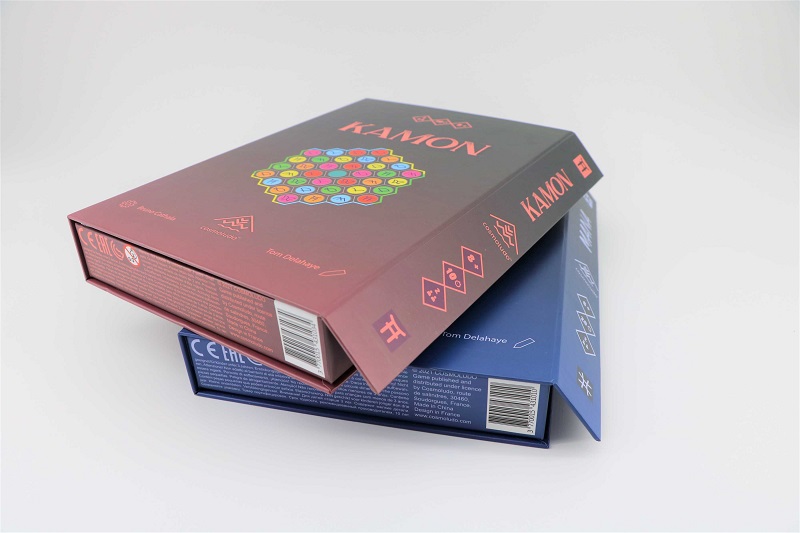

As you can't imagine, playing cards have been around for a very long time. Playing cards were invented in China around the 11th century. After Chinese solitaire was introduced to Europe, four types of cards were used, but different names and cultural connotations were given to each country. Here, follow our board game manufacturer HOPES to see how playing cards are made.

The paper used for playing cards is custom made by a paper mill. Two layers of cardboard are glued together with colored glue. This construction prevents the cardboard from being seen through.

Workers regularly test the temperature and humidity of the paper. A deck of 54 cards was printed on the same sheet of cardboard and the whole was cut into sheets.

Before making the printing template, the technician checks the design of the cardboard. Not only do they check the version on the computer, but they also print out a low-resolution sample drawing and carefully check the suit, order, color and layout of each card to confirm the correctness of the sample drawing before printing.

The next step is to create a digital proof, also known as a film. A special printer's internal laser transfers the heat from the colored foil dots to the blank film. These dots perfectly reproduce the content and color of each card. The film is then exposed with a dolly press and pressed onto cardboard for playing cards, creating a proof sheet that can look exactly like the printed card.

The manufacturer compares the printed proofs and allows the graphic designer to make adjustments to the hand-drawn playing cards, such as adding colors and details to make the cards more gorgeous. After this round of operations, the layout of the playing cards is officially completed.

Before printing, the physical drawing is made first. A computer-controlled laser etches the new design electronically onto the surface of the polymer printing plate. The etching process is relatively slow. The machine below can only produce 30 patterns per hour.

Workers then inject thick, blue, black, red and yellow ink into the cartridges of the industrial press. Each color of ink passes through 16 rollers to ensure even spraying. The paper feeder uses negative pressure adsorption to feed the pile of paper into the printer one by one.

After the front and back are printed, the cardboard is fed into the cutter, where a rotating roller knife first cuts the cardboard into strips. Cross-cut into individual cards.

The playing cards are pushed onto a conveyor belt and wrapped in cellophane. Each time the plastic wrapping is sealed, a mechanical arm grabs the cellophane reel and pulls it down. After the playing cards are wrapped, the heating rod is lowered to seal the plastic into an envelope.

Now please contact us to get your custom cards.